A word of caution: this article wasn’t written for companies with million-dollar ERP systems and teams of analysts. Although, you are welcome to keep reading. This is for “our people” — growing and scrappy manufacturers working for continuous improvement and looking for partners, not just software vendors. xTuple is comprised of manufacturing and ERP subject matter experts. We get manufacturing and want to help our people make it better.

Key Performance Indicators — KPIs

As you know, KPIs are the most important metrics of business activity- proving (or disproving) whether processes work. More importantly, KPIs highlight a direct path to how and where resources are being used wisely or wasted needlessly.

What does this have to do with ERP? Everything.

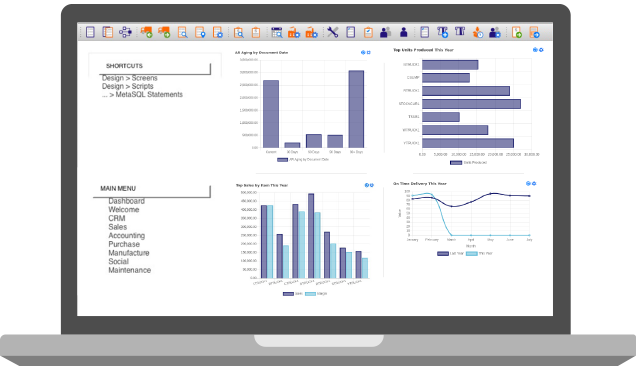

A solid ERP system — deployed, managed and used effectively — is how you gather, store and manage all the information needed to improve productivity and performance for sustainable profitability.

What is the difference between “productivity” and “performance”?

At xTuple, when we speak of productivity, it is in relation to everything a company does — it is the “how much” — products produced, labor hours worked, top-line sales achieved, etc. When we speak of performance, we are referring to “how well” a company is doing it. For example, really fast production may mean more product on the market and great topline sales. However, if the product return rate is high, then margins are thinner. This example demonstrates the critical need for performance metrics. How do you know how much you need to slow or simply adjust production to reduce returns and increase margins? Here’s how — track, measure, adjust, repeat.

That’s where ERP and KPIs come in (along with a slew of other acronyms). While that may seem a bit “buy low/sell high,” without measuring all the factors that impact each of the variables — such as raw materials, labor hours, cash-to-cash cycles times and others — you can’t really find the ideal balance between how well and how much you produce to achieve sustainable profitability.

Track. Measure. Adjust. Repeat.

Ultimately, everything you track, measure and compare is to accomplish three things, which really all lead back to one: reducing costs.

KPIs give you the visibility to see trends over time, quickly identify problem areas and avoid major pitfalls that can impact business. Simply put, KPIs help us learn from mistakes, fix problems before they happen and, ultimately, make more money.

What to measure and why.

Of course, top-line revenue is the primary indicator of your productivity — how well your teams work to make, sell and deliver products. But the ultimate test of your model is profitability: how much you keep and are able to reinvest in your company’s growth.

No matter how much revenue you generate, there are costs associated. Increasing profitability is dependent on understanding and reducing costs — but naturally, not at the expense of the quality of your product or safety of your employees.

The following are intended as a jumping off point. We invite you to download our White Paper: The KPIs — Key Performance Indicators — Manufacturers Should be Measuring & Why.

Reduce Costs

Ultimately, everything you do more efficiently will reduce costs — from eliminating the human errors associated with redundant and manual tasks to buying raw materials and supplies in bulk to getting a better price to refining your production processes to increasing finished goods. Start with more insight into costs that you can more easily control.

Total Manufacturing Cost per Unit Excluding Materials

This allows you to measure the cost of a single unit in labor and overhead costs. Why does this matter?

Average Unit Contribution Margin

Average Unit Contribution Margin represents the incremental money generated for each product/unit sold after deducting the variable portion of the company’s costs. Measuring average contribution margin helps you understand the impact by unit of additional sales to the bottom line. Why does this matter?

Cash-to-Cash Cycle Time

This measures the time between the purchase of inventory and the collection of payments for the sale of the products that utilize that inventory. How does this help?

You get the picture. For more insight, download our White Paper: The KPIs – Key Performance Indicators – Manufacturers Should be Measuring & Why and don’t miss our May 20 webinar, Manufacturing Finance 101.

Contact

xTuple

A CAI Software Company

24 Albion Rd, Suite 230

Lincoln, RI 02865

+1-757-461-3022

About

"xTuple" (verb) — to grow; to increase exponentially. Our mission is to help manufacturing and inventory-centric companies use management software and best practices to grow their business profitably.